Our manufacturing facility

Your products are shipped from this location to your building sites and agencies throughout France and in over 40 countries.

In order to offer products of the highest quality, all our processes are subject to stringent daily quality controls and audits, with the goal of ensuring the customer’s utmost satisfaction.

Our French know-how is entirely exported from the Isère department. How do we do it?

A proven commitment to quality and safety

Thanks to our quality control team that focuses on production, as well as both visual and sizing verifications, our products are meticulously monitored throughout the process to ensure their compliance with precise design briefs.

Workstations, tooling, machinery, and devices are also verified daily to ensure quality and overall safety.

Origine France Garantie certified products

Our automatic doors, swing door operators and dock levellers are designed and produced in France, near Grenoble (Isère).

This certification testifies to our unwavering determination to offer our customers solutions whose origin is clear and indisputable.

The label attests to our commitment to local, high-quality production, thereby helping to boost the French economy.

High-performance materials and components

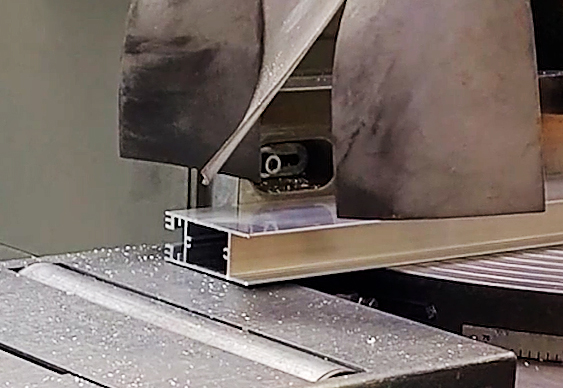

Aluminum

for the chassis

- Light

- Corrosion resistant

- Rugged

- Versatile

- Thermal conductivity

- Recyclable

Glass

for filling

- Transparent

- Attractive

- Secure

- Easy to clean

- Versatile design

- Many configurations

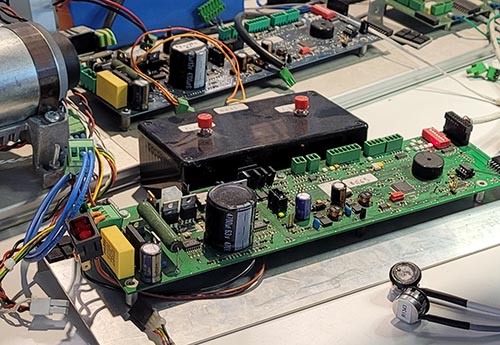

Electronics

and technology

- Advanced motion detectors

- Speed and force control

- Integrated security system

- Remote commands and connectivity

- Reliability and durability